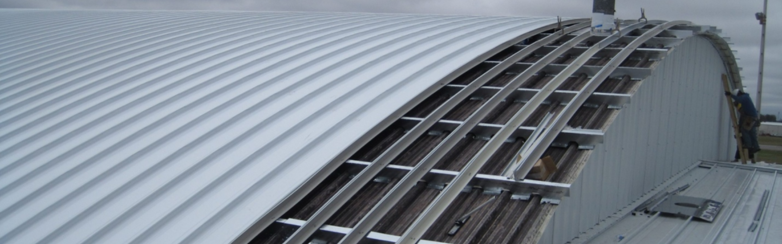

Roof Seaming Works

VCI’s Standing Seam System emerges as a pioneering solution, leading the transformation of airport design. It offers unparalleled design flexibility, empowering architects to bring their ambitious and distinctive design visions to life at airports worldwide. With VCI’s seaming sytem, architects are free from the constraints of traditional materials, enabling the creation of airport structures that are not only visually captivating but also functionally efficient. The system has garnered widespread preference among architects designing airport terminals and hangars globally, with notable project references encompassing GMR Air Cargo, Goa Airport, RGIA and numerous.

Tailored Length Options: VCI’s stands out due to its exceptional versatility in length options. The VCI’s Linea sheet is available in factory-rolled lengths that span from 1.0 meter to a noteworthy 15.0 meters. Additionally, for on-site requirements, machine-rolled lengths range from 1.0 m up to 150.0 m. Expanding on this versatility, lengths can be extended from 1 meter to those achievable with the VCI’s Infiniti using on-site rolling machines. This adaptability ensures that the roofing system can be fine-tuned to align perfectly with the diverse requirements of airport projects, irrespective of their magnitude or intricacy. It's also pertinent to mention that the minimum lengths can be adjusted to accommodate project-specific conditions, and factory roll-forming can be customized to align with project necessities and logistical considerations.

With the above in perspective, in our roofing designs utilizing the VCI’s Standing Seam, we endeavor to use a single sheet from Ridge to Eave, ensuring no overlaps or mid-seam joints, resulting in a fully watertight roofing system.

Contact us